Telephone

025-52791167,52791168

13390905858

13390905858

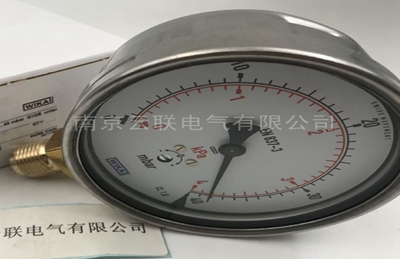

Process connector for Wika diaphragm pressure gauge 233

Thread GB (external thread) and GB (external thread), in accordance with EN 837-1 standard, without locating protrusions

Thread G, G (internal thread)

Thread NPT, NPT (external thread)

Thread NPT, NPT (internal thread)

Other connectors to be provided as required

Application of Wika diaphragm pressure gauge 990.34

Suitable for corrosive, contaminated, or high-temperature pressure media

Chemical processing industry

Petrochemical industry

water treatment

Functional characteristics of 990.34

Fully welded structure

Multiple materials available

Suitable for high-pressure applications

The Wika stainless steel pressure gauge uses direct contact connectors and pressure sensing element materials, including icr18Ni9T, 316L, Monel alloy, Hastelloy alloy, etc. The structure is fully sealed, and the stainless steel pressure gauge has strong resistance to corrosion of the tested medium and environmental corrosion. Wika stainless steel pressure gauges are suitable for corrosive media suitable for detecting stainless steel components and harsh external corrosive environments. German Wika stainless steel pressure gauges are widely used in industries such as petroleum, chemical, and metallurgy.

describe

Pressure range and diaphragm diameter

The maximum pressure range (Mb) depends on the effective diameter of the diaphragm and the operating temperature (+50 ℃)

Mb 22 mm: 0 100 MPa

Mb 29 mm: 0 60 MPa

Mb 40 mm: 0 40 MPa

Mb 52 mm: 0 16 MPa

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100