Knowledge for this issue – Installation of buffers.

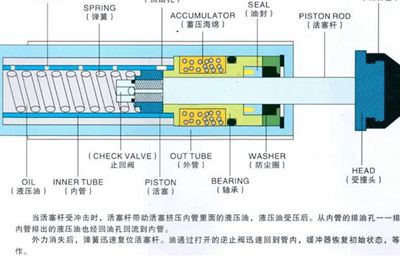

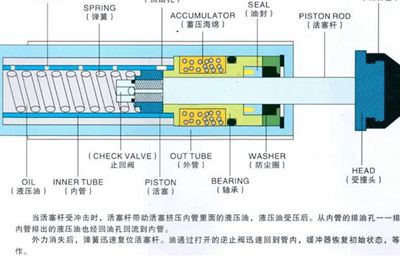

Firstly, let’s understand the function of a buffer. Buffer is a product installed between pipeline joints, flanges, or other flat surfaces to reduce friction and vibration between moving parts. It can withstand high pressure and temperature, while effectively preventing wear on the mating surface and extending the service life of the equipment.

The installation steps of the buffer. Before installation, it is necessary to ensure the cleanliness and safety of the installation site. Then, tighten the bolts on both sides of the buffer evenly until the bolt markings meet the requirements. Be careful not to overtighten to avoid damaging the buffer. Next, place the sealing rings on both sides into the appropriate slots and secure them with nuts. Finally, install the buffer in the desired location and check for stability. If there are any problems, the bolts and nuts can be adjusted appropriately.

The installation process of the buffer is simple and convenient, which not only effectively reduces vibration and noise, prolongs the service life of the equipment, but also ensures the aesthetic and standardized installation.