Telephone

025-52791167,52791168

13390905858

13390905858

Distance Adjustment and Usage of Buffer

Buffer plays a crucial role in various mechanical equipment. It can effectively reduce impact force and protect the safety of equipment and operators. Next, let’s take a detailed look at the distance adjustment and usage of the buffer.

1、 The Importance of Buffer

Buffer can absorb and reduce the impact force caused by rapid start stop, collision, etc. of moving parts during the operation of the equipment. This can not only extend the service life of the equipment, but also reduce noise, improve the stability and reliability of the equipment. For some devices that require high precision, buffers are an indispensable component.

2、 Classification of buffers

Common buffers mainly include hydraulic buffers and hydraulic buffers. Hydraulic buffers slow down objects through hydraulic damping, which has the advantages of fast response speed and good buffering effect. The hydraulic buffer uses the pressure of oil to achieve buffering, which is suitable for situations with large impact forces.

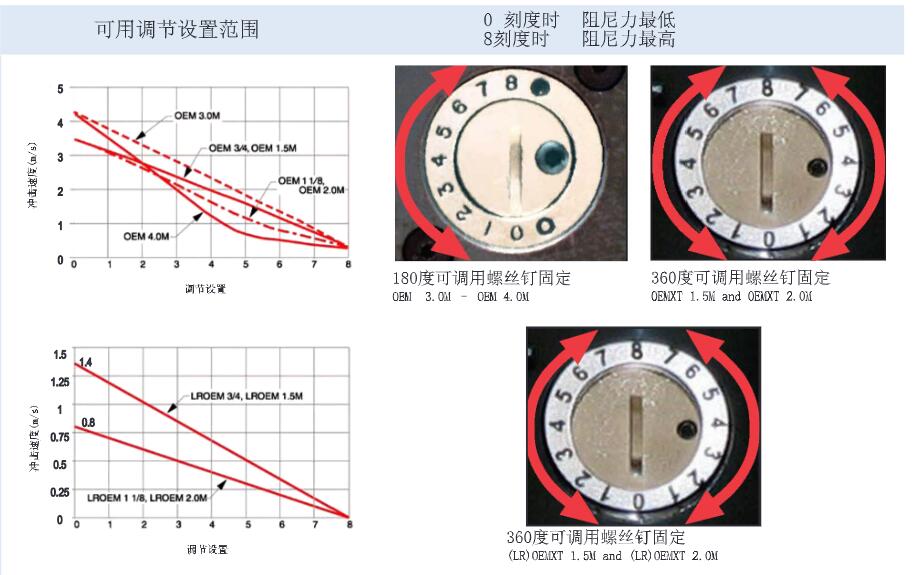

3、 Adjustment of buffer distance

1. Determine the adjustment requirements

Before adjusting the distance, it is necessary to first clarify the working requirements and motion trajectory of the equipment. Determine the appropriate buffer distance based on different application scenarios to ensure that the buffer can function effectively at critical moments.

2. Adjustment method

For hydraulic buffers, the buffering distance can be changed by adjusting the size of the damping holes inside or the flow rate of hydraulic oil. Generally speaking, increasing the damping hole or reducing the hydraulic oil flow rate can increase the buffering distance, otherwise it can decrease the buffering distance. Oil pressure buffers can usually achieve distance adjustment by adjusting the preload force of their springs or the size of the oil pressure.

4、 How to use the buffer

(1) Instructions for using hydraulic buffer

1. Installation environment

Hydraulic buffers should be installed in a dry and clean environment to avoid being affected by impurities such as dust and moisture. During installation, ensure that the buffer is installed in the correct position and connected firmly and reliably to the moving parts.

2. Working principle

When the moving parts come into contact with the hydraulic buffer, hydraulic oil flows through the damping holes, generating resistance and slowing down the speed of the moving parts. In this process, the hydraulic buffer converts the impact force into thermal energy and hydraulic energy, achieving the purpose of buffering.

3. Precautions

When using hydraulic buffers, it is necessary to regularly check the level and quality of hydraulic oil, and replace deteriorated hydraulic oil in a timely manner. At the same time, it is important to avoid excessive impact and vibration on the buffer to avoid affecting its performance and lifespan.

(2) Instructions for using hydraulic buffer

1. Common uses

Hydraulic buffers are widely used in industrial machinery, such as cranes, elevators, conveying equipment, etc. It can effectively absorb and reduce impact forces during equipment operation, protecting the safety of equipment and operators.

2. Standardized operation

When installing and using hydraulic buffers, strictly follow the instructions in the manual. Ensure that the installation position of the buffer is correct and the connection is firm. During use, pay attention to observing the working status of the buffer. If any abnormal situation is found, stop the machine for inspection in a timely manner.

3. Safety and Fire Prevention

Due to the presence of hydraulic oil in the hydraulic buffer, attention should be paid to fire safety during use. Avoid the buffer from being affected by high temperatures, fire sources, etc., to prevent fire accidents. At the same time, it is necessary to regularly check the sealing of the buffer to prevent hydraulic oil leakage.

In short, correctly adjusting the distance of the buffer and mastering its usage method are of great significance for ensuring the safe operation of the equipment and extending its service life. In practical applications, we should choose the appropriate buffer type according to different equipment and work requirements, and strictly follow the operating procedures for installation and use.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100