Telephone

025-52791167,52791168

13390905858

13390905858

What is the basic structure and working principle of a cylinder?

In the modern industrial field, cylinders are widely used as important pneumatic actuators in various automation equipment and mechanical systems. It provides strong support for the automation and mechanization of the production process with its simple structure, reliable performance, and efficient working mode.

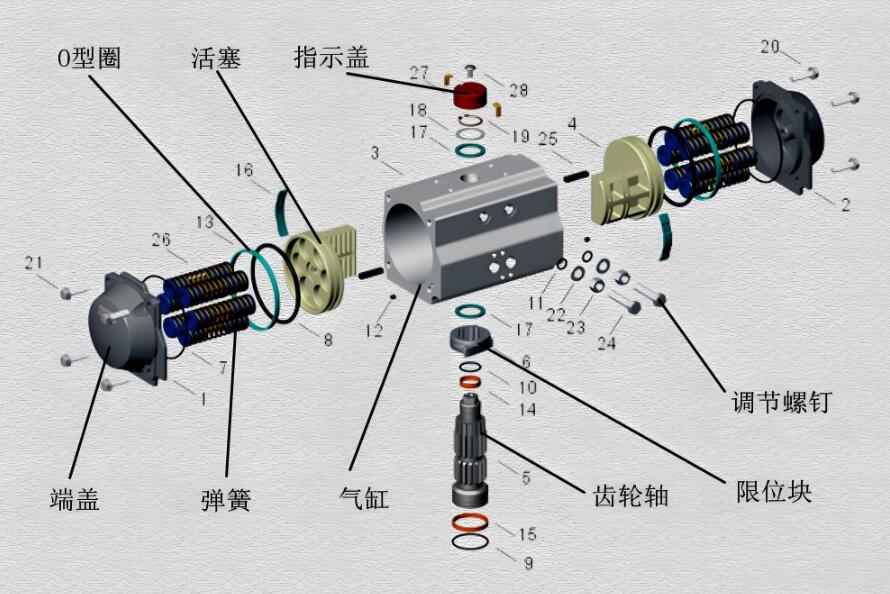

1、 Basic structure of cylinder

A cylinder is mainly composed of a cylinder barrel, end cap, piston, piston rod, and sealing components.

Cylinder barrel

The cylinder barrel is the main body of the cylinder, usually made of high-strength metal materials such as aluminum alloy, cast iron, etc. The interior of the cylinder is smooth and flat, providing a sealed space for the movement of the piston. The outer diameter of the cylinder barrel is usually machined with installation threads or holes to secure the cylinder to mechanical equipment.

End cap

End caps are installed at both ends of the cylinder to seal the cylinder and support the piston and piston rod. There are usually intake and exhaust ports on the end cap, which are used to control the intake and exhaust of the cylinder. Seals are usually used between the end cap and the cylinder barrel to ensure the airtightness inside the cylinder.

piston

The piston is a moving component in the cylinder, which performs reciprocating linear motion inside the cylinder. Pistons are usually made of high-strength metal materials such as aluminum alloy, cast iron, etc. The outer surface of the piston is usually machined with sealing grooves for installing seals to prevent gas leakage. The piston is usually equipped with a piston ring to improve the sealing between the piston and the cylinder.

piston rod

The piston rod is a component that connects the piston and the external actuator, transmitting the linear motion of the piston to the external actuator. The piston rod is usually made of high-strength metal materials such as stainless steel, alloy steel, etc. The outer surface of the piston rod is usually machined with a smooth surface to reduce friction with the seal.

Sealing element

Seals are key components used in cylinders to ensure airtightness. Seals are usually installed in the sealing groove between the piston, piston rod, and cylinder to prevent gas leakage. There are many types of seals, commonly including O-ring seals, Y-shaped seals, V-shaped seals, etc.

2、 Working principle of cylinder

The working principle of a cylinder is to use the pressure energy of compressed air to push the piston to make reciprocating linear motion inside the cylinder, thereby realizing the process of converting the pressure energy of compressed air into mechanical energy.

Single acting cylinder

A single acting cylinder has only one intake port, and compressed air enters the cylinder through the intake port, pushing the piston forward. When the compressed air supply stops, the piston returns to its original position under the action of spring or gravity. The structure of a single acting cylinder is simple, but its output force is small, making it suitable for situations with small loads.

Double acting cylinder

The double acting cylinder has two intake ports, which are used to control the forward and backward movement of the piston. When compressed air enters the cylinder from an intake port, it pushes the piston forward; When compressed air enters the cylinder from another intake port, it pushes the piston backwards. The dual acting cylinder has a high output force and is suitable for situations with large loads.

3、 Application of cylinders

Cylinders have a wide range of applications in industrial production, such as the following aspects:

automatic production line

On automated production lines, cylinders can be used to carry, clamp, and position various materials. For example, in the automotive manufacturing industry, cylinders can be used for processes such as welding and assembly of car bodies.

mechanical equipment

In mechanical equipment, cylinders can be used to control various movements, such as feed, clamping, positioning, and other operations of machine tools. For example, in CNC machine tools, cylinders can be used for automatic tool changing operations.

Packaging Machinery

In packaging machinery, cylinders can be used to transport, clamp, seal and other operations of various packaging materials. For example, in the food packaging industry, cylinders can be used for processes such as filling and sealing food.

Manufacturing of electronic devices

In the electronic device manufacturing industry, cylinders can be used to perform various operations such as assembly and testing of electronic components. For example, in the mobile phone manufacturing industry, cylinders can be used for processes such as screen fitting and assembly.

In short, as an important pneumatic actuator, the cylinder has the advantages of simple structure, high reliability, large output force, and easy maintenance. In modern industrial production, the application of cylinders is becoming increasingly widespread, playing an important role in improving production efficiency, reducing production costs, and enhancing product quality.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100