Telephone

025-52791167,52791168

13390905858

13390905858

Working principle of pneumatic diaphragm pump

Pneumatic diaphragm pump is a new type of conveying machinery that uses compressed air as the power source. It can pump and absorb various corrosive liquids, granular liquids, high viscosity, volatile, flammable, and highly toxic liquids.

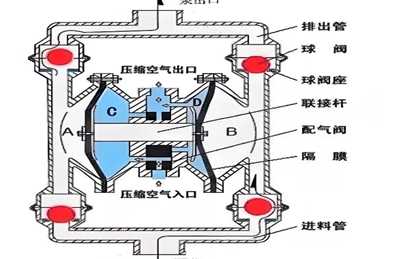

1、 Structure of Pneumatic Diaphragm Pump

Pneumatic diaphragm pump mainly consists of the following parts:

Pneumatic motor: driven by compressed air, converting the pressure energy of air into mechanical energy.

Diaphragm: Usually made of elastic materials such as rubber or plastic, it divides the working chamber of the pump into two chambers.

Import and export one-way valve: controls the direction of liquid inlet and outlet, ensuring that the liquid can only flow in one direction.

Pump body: accommodates the diaphragm and other components, providing a channel for liquid flow.

2、 Working principle

Inhalation process

When compressed air enters the pneumatic motor, it pushes the piston in the motor to move.

The piston is connected to the diaphragm through a connecting rod, which drives the diaphragm to move to one side, increasing the volume of a chamber in the pump’s working chamber and creating negative pressure.

At this point, the inlet one-way valve opens and the outlet one-way valve closes, and the liquid is sucked into the chamber under atmospheric pressure.

Drainage process

As compressed air continues to enter, the piston continues to move, and when it reaches a certain position, the compressed air pushes the piston to move in the opposite direction.

The diaphragm also moves to the other side, causing the volume of the chamber that just sucked in the liquid to decrease and the pressure to increase.

At this point, the inlet one-way valve is closed, the outlet one-way valve is opened, and the liquid is squeezed out of the chamber and enters the discharge pipeline.

Circular work

In this repeated cycle, the pneumatic diaphragm pump continuously sucks in and discharges liquid, achieving the transportation of liquid.

3、 Characteristics

No need for electric drive, can be used in flammable and explosive places, with high safety.

It can transport various corrosive, high viscosity, granular and other special liquids.

Simple structure, small size, light weight, easy to install and maintain.

It has self-priming ability and can be started without the need for pumping.

The flow rate can be adjusted, and the output flow rate of the pump can be controlled by adjusting the flow rate and pressure of the compressed air.

Smooth operation without vibration or noise.

4、 Application Fields

Chemical industry: used for transporting various corrosive liquids, flammable and explosive liquids, high viscosity liquids, etc.

Environmental protection industry: used for sewage treatment, sludge transportation, etc.

Food industry: used for transporting food raw materials, sauces, juices, etc.

Pharmaceutical industry: used for transporting drugs, pharmaceuticals, etc.

Mining industry: used for transporting mineral slurry, tailings, etc.

In short, pneumatic diaphragm pumps have been widely used in many fields due to their unique working principles and characteristics.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100