Telephone

025-52791167,52791168

13390905858

13390905858

Introduction and Analysis of Pneumatic Electromagnetic Valve and Pulse Electromagnetic Valve

Pneumatic solenoid valves and pulse solenoid valves play extremely important roles in industrial automation control and numerous fluid control systems, serving different application scenarios with their unique working principles and functional characteristics. The following will provide a detailed introduction to the relevant knowledge of these two types of solenoid valves.

Pneumatic solenoid valve

Basic Structure and Composition

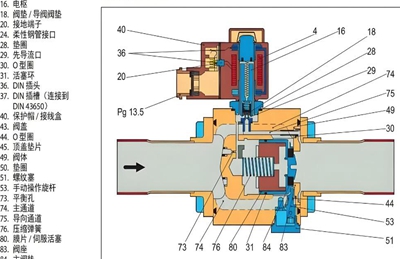

Pneumatic solenoid valves are mainly composed of valve body, valve core, electromagnetic coil, spring and other components. The valve body is generally made of metal material, providing structural support and fluid channels for the entire solenoid valve. The internal channel design can have various forms according to different application requirements, such as two-way, three-way, four-way, etc., to achieve different flow directions and control functions.

As a key moving component, the valve core can move inside the valve body under the action of electromagnetic force and spring force, thereby changing the flow path state of the fluid. The electromagnetic coil is the source of electromagnetic force. When an electric current is applied, it generates a magnetic field that attracts the valve core to move. The function of a spring is usually to rely on its own elastic force to push the valve core back to its original working state in the event of a power outage, ensuring that the solenoid valve returns to its initial working state.

working principle

Pneumatic solenoid valves use electromagnetic force as the driving force to control the direction, on/off state, and other aspects of gas flow. When the electromagnetic coil is energized, the generated magnetic field overcomes the elastic force of the spring, attracts the valve core to move, opens the originally closed gas channel, or changes the flow direction of the gas, allowing the gas to flow according to the predetermined route, and then drives the connected pneumatic actuators, such as cylinders and motors, to work. Once the electromagnetic coil is powered off, the electromagnetic force disappears, and under the action of the spring force, the valve core returns to its original position, the gas channel returns to its initial state, and the corresponding pneumatic action stops.

For example, in the cylinder driven grasping device on the automated production line, the on/off control of the pneumatic solenoid valve can accurately control the expansion and contraction of the cylinder, achieve the grasping and lowering operation of the workpiece, and meet the different process requirements in the production process.

Classification and Characteristics

According to their functions, pneumatic solenoid valves can be classified into normally closed and normally open types. Normally closed type: The gas channel is closed under normal conditions (power off) and only opens when powered on; The normally open type is the opposite, the channel is open under normal conditions and closes after being powered on.

From the perspective of the number of ports and channel forms, there are various types such as two-way, three-way, four-way, etc. Two way solenoid valves are mainly used for simple gas on-off control; Three way solenoid valves can achieve functions such as intake, exhaust, and switching airflow directions, and are commonly used in situations where flexible control of one end of the cylinder for intake and the other end for exhaust is required; A four-way solenoid valve can more conveniently control the bidirectional movement of a double acting cylinder, achieving more complex pneumatic actions.

Pneumatic solenoid valves have the characteristic of fast response speed, which can complete the action of the valve core in a short time and control the airflow, making them excellent in automation systems that require fast action. At the same time, its structure is relatively simple and compact, easy to install and maintain, and its reliability is also relatively high. It can work stably in long-term industrial operating environments.

application area

Pneumatic solenoid valves are widely used in many industrial fields such as mechanical manufacturing, automotive production, food packaging, and automated logistics. In mechanical manufacturing, pneumatic clamping devices are used to control machine tools and ensure the stability of workpieces during the machining process; On the automobile production line, a large number of pneumatic solenoid valves are involved in processes such as door installation and component assembly, accurately controlling the movement of pneumatic tools; In the food packaging industry, being able to cooperate with pneumatic equipment to complete packaging bag sealing, material transportation and other operations, ensuring the efficiency and hygiene of the packaging process.

Pulse electromagnetic valve

Basic Structure and Composition

Pulse solenoid valve also includes basic components such as valve body, valve core, and electromagnetic coil, but its structural design will focus more on meeting the requirements of pulse signal control. The layout of internal channels in the valve body needs to consider the ability to accurately achieve corresponding fluid control functions under short and intermittent pulse signals. The motion characteristics of the valve core and the precision of its fit with the valve body require high precision to ensure the accuracy of its action under pulse driving. The design of electromagnetic coils will also be optimized based on parameters such as voltage and current controlled by pulses to ensure reliable response to pulse electrical signals.

working principle

Pulse solenoid valves operate by receiving pulse electrical signals. Pulse signal is an intermittent electrical signal with specific time intervals and widths. When the pulse solenoid valve receives a pulse signal, the electromagnetic coil is instantly energized, generating electromagnetic force that causes the valve core to produce corresponding actions, achieving temporary opening or closing of fluid channels, instantaneous changes in flow direction, and other operations. After the pulse ends, relying on the reset mechanism of the valve core itself (such as the elastic force of the spring, etc.), the valve core returns to its initial position and waits for the next pulse signal to arrive.

For example, in a bag filter, the pulse solenoid valve sends a pulse airflow to the spray pipe according to the set pulse interval and width, causing compressed air to be sprayed into the bag in a short time and with high intensity, effectively shaking off and cleaning the dust on the surface of the bag, ensuring the filtering effect of the bag filter.

Classification and Characteristics

According to their functional characteristics, they can be divided into right angle pulse solenoid valves, submerged pulse solenoid valves, etc. The inlet and outlet channels of the right angle pulse solenoid valve are arranged at right angles, and the installation space requirements are relatively flexible; Submerged pulse solenoid valves are usually installed inside the airbag, with good overall sealing performance, and are more suitable for situations that require protection and compact installation.

The significant feature of pulse solenoid valve is that it can work accurately according to pulse signals, achieving intermittent and periodic fluid control, which makes it very suitable for situations that require timed and quantitative fluid control. And it can generate significant fluid impact force in a short period of time, which can be efficiently used to clean dust and other impurities in applications such as dust collectors.

application area

Pulse electromagnetic valves are widely used in the field of environmental protection. In addition to the bag filter mentioned above, they are key control components in various dust removal equipment such as electrostatic precipitators, used for dust cleaning operations and maintaining good dust removal performance of the equipment. Meanwhile, in the irrigation system, intermittent spraying of water can be achieved according to the set pulse parameters, improving the uniformity of irrigation and the efficiency of water resource utilization; In some chemical production

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100