How to ensure the effective implementation of

buffer distance standards?

The establishment of buffer distance standards is to ensure the safe and stable operation of numerous devices and systems in the face of impact. However, standards alone are not enough. The key is how to ensure that these standards are effectively implemented in practice. The following will explore this important issue from several aspects.

Rigorous control during the design phase

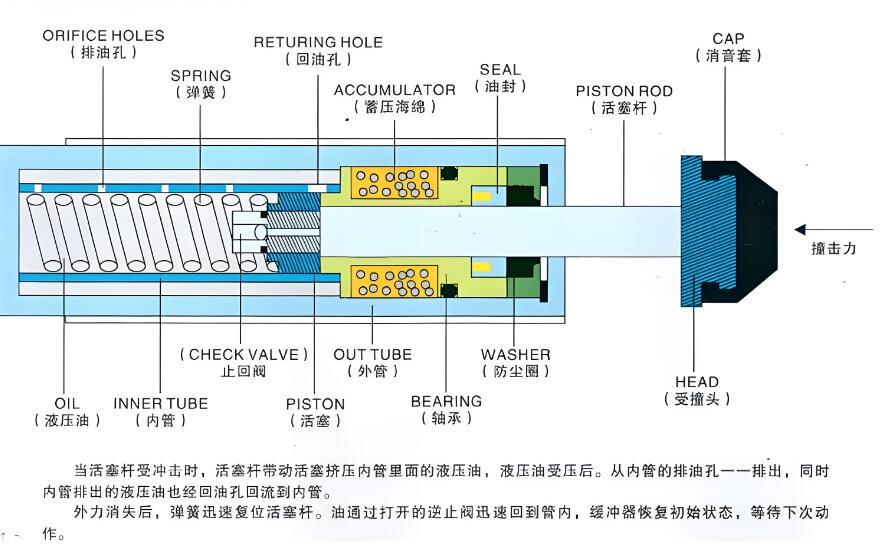

In the initial design stage of the equipment, it is necessary to incorporate the buffer distance standard into the overall design considerations. Design engineers need to accurately calculate and determine the reasonable installation position and corresponding distance standards for buffers based on detailed parameters such as the expected use, operating speed, maximum load capacity, and selected buffer type of the equipment. For example, when designing a new type of high-speed elevator, it is necessary to fully consider the maximum impact force that the car may generate during high-speed operation, combined with the performance curve of the selected hydraulic buffer, accurately plan the buffer distance of the buffer, so that it can meet the standard requirements and achieve the best buffering effect in extreme situations.

At the same time, in the design process, advanced simulation software needs to be used for virtual modeling and simulation analysis to simulate the working conditions of the buffer under different working conditions and verify whether the set distance standards are appropriate. If any unreasonable buffer distance is found in the simulation, such as causing premature saturation or insufficient travel of the buffer, the design should be adjusted in a timely manner to ensure the scientific and feasibility of the buffer distance standard from the source.

Accurate construction in the installation process

The installation of buffers is a crucial step in ensuring the achievement of distance standards. Installation personnel must possess professional skills and qualifications, and operate strictly in accordance with the design drawings and relevant standards and specifications. When installing elevator buffers, precise measuring tools such as laser rangefinders should be used to accurately measure the installation height of the buffer and the relative distance to components such as the car and counterweight, ensuring that the error is controlled within the allowable minimum range. For the installation of railway vehicle buffers, it should be carried out on specific tooling equipment in the vehicle manufacturing workshop to ensure that the spacing between adjacent vehicle

buffers meets the prescribed standards, and multiple rechecks and calibrations should be conducted to avoid buffering problems caused by improper installation during subsequent vehicle grouping and operation.

In addition, it is necessary to keep installation records during the installation process, detailing key information such as the model, installation location, and actual measured distance of the buffer, so that subsequent maintenance and inspection work can be traceable and potential distance deviations can be detected in a timely manner.

Strengthening daily maintenance and regular inspections

After the equipment is put into use, daily maintenance and regular inspection work are crucial for maintaining the effectiveness of the buffer distance standard. Maintenance personnel should regularly inspect the appearance of the buffer to see if there are any damaged or deformed components that affect its buffering distance. For example, when inspecting the elevator buffer, if the spring of the buffer is found to be corroded, deformed, or if the hydraulic buffer has oil leakage, it needs to be repaired or replaced in a timely manner, and the buffer distance needs to be remeasured to ensure that it still meets the standard requirements.

Regular professional inspections are essential, and relevant regulatory departments and professional inspection agencies should conduct comprehensive testing of buffer distance standards using professional testing equipment according to established cycles. When inspecting railway vehicle buffers, precise measuring tools are used to measure the distance between buffers after the train is parked at a specific maintenance site. Combined with the vehicle’s mileage, load capacity, and other factors, a comprehensive judgment is made on whether the buffers can still function normally within the specified distance standard. For situations that do not meet the standards, a rectification notice should be issued to urge the user unit to rectify within a specified period of time. Only in this way can the buffer always perform its buffering function according to the standard requirements and ensure the safe operation of the entire equipment system.

Only through strict control of design, installation, maintenance, and inspection can the effective implementation of buffer distance standards be ensured, and buffers continue to contribute to safety in various fields.