Telephone

025-52791167,52791168

13390905858

13390905858

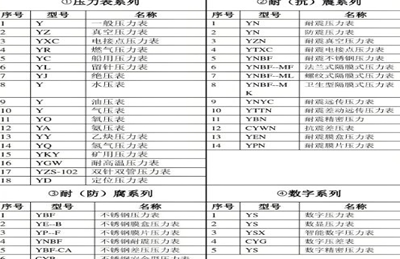

Introduction to specifications and models of pressure gauges

Pressure gauges play a crucial role in industrial manufacturing, energy and chemical industries, as well as numerous engineering fields. The diversity of their specifications and models also provides strong guarantees for meeting various complex working conditions.

1、 Detailed explanation of pressure gauge specifications

Connection method specifications

The connection method of a pressure gauge is an important aspect of its specifications, commonly including threaded connections, flange connections, etc. Threaded connections are divided into different specifications of thread forms such as M20 × 1.5 and G1/2. The M20 × 1.5 metric thread connection method is widely used and is commonly used in small mechanical equipment and simple pipeline systems. Its connection is firm and easy to install. And G1/2 British pipe threads are often used in projects that are matched with imported equipment or follow international standards. For example, in some automated production lines introduced by foreign-funded enterprises, using G1/2 thread connections for pressure monitoring pressure gauges can better adapt to the overall equipment piping system. Flange connection is suitable for large-diameter pipelines or harsh working conditions such as high pressure and high temperature. For example, the main steam pipeline of a thermal power plant usually uses flange connection pressure gauges with specifications such as DN80 and PN16, which are easy to install, disassemble, and ensure sealing performance to prevent medium leakage.

Material specifications

The shell and internal components of the pressure gauge will be made of different materials depending on the measuring medium in contact. For measuring non corrosive media such as water and air, the pressure gauge housing is often made of ordinary carbon steel, and key components such as the internal spring tube are made of brass, which is low-cost and can meet basic measurement requirements. However, in the chemical industry, when facing highly corrosive media such as hydrochloric acid and sulfuric acid, the outer shell of the pressure gauge will be made of stainless steel 316L material, which has good corrosion resistance. The internal spring tube will also be made of special corrosion-resistant alloy materials, such as Hastelloy, to ensure that the pressure gauge can work stably for a long time in harsh chemical environments and accurately measure pressure. In the food and beverage industry, considering hygiene requirements, pressure gauges are often made of stainless steel 304 material, with a smooth and easy to clean surface that meets relevant standards for food production.

Environmental adaptability specifications

Pressure gauges need to work under different environmental conditions, so their environmental adaptability specifications also vary. Some pressure gauges can adapt to a narrow working temperature range, such as indoor pressure gauges for general civilian use, with a normal working temperature between -10 ℃ and 50 ℃; In industrial high-temperature environments, pressure gauges used to measure gas pressure near steelmaking furnaces in steel plants need to be able to withstand temperatures as high as 600 ℃ or even higher. They are made of special insulation and high-temperature resistant materials to ensure normal measurement even under extreme high temperatures. Similarly, in low-temperature environments such as liquid nitrogen storage tank pressure monitoring, the pressure gauge should be able to work stably under ultra-low temperature conditions such as -196 ℃. The internal seals, lubricating oil, etc. are made of special materials that are resistant to low temperatures to ensure their performance.

2、 Classification and Characteristics of Pressure Gauge Models

Diaphragm pressure gauge model

Common models of diaphragm pressure gauges include YTP-60, YTP-100, etc. The “P” in “YTP” represents “diaphragm”. This type of pressure gauge isolates the measuring medium from the sensitive components inside the pressure gauge through a diaphragm, and is suitable for measuring the pressure of special media such as those that are prone to solidification, crystallization, strong corrosiveness, and high viscosity. For example, in the pharmaceutical industry, for some drug delivery pipelines containing high concentrations of chemical agents that are prone to crystallization and blockage of ordinary pressure gauges, the use of diaphragm pressure gauges can effectively solve the problem, accurately measure the pressure inside the pipeline, and ensure the smooth production process.

Remote transmission pressure gauge model

For example, YCZ-100, YCZ-150, etc., “YCZ” represents “remote pressure gauge”. It can remotely transmit the measured pressure signal to the control center or other monitoring equipment through an electrical conversion device, achieving the function of remote pressure monitoring. In large water supply pump stations, operators do not need to go to the site to check the pressure gauge readings at the outlet of each water pump. By remotely transmitting the pressure gauge, they can grasp the pressure situation in real time in the central control room, making it convenient to adjust the operating parameters of the water pump in a timely manner, and improving the stability and efficiency of water supply.

Stainless steel pressure gauge model

There are many models of stainless steel pressure gauges, such as YB-60, YB-100, etc. Their characteristic is that they are made of stainless steel material as a whole, with a beautiful appearance and strong corrosion resistance. In the field of ocean engineering, such as offshore oil drilling platforms, they are subject to long-term erosion by harsh environments such as seawater and sea breeze. Stainless steel pressure gauges can reliably measure the pressure of various hydraulic systems, seawater treatment systems, etc., ensuring the normal operation of the platform.

Through a deep understanding of the specifications and models of pressure gauges, we can accurately select suitable pressure gauges based on actual application scenarios and needs, providing reliable guarantees for various pressure measurement work.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100