Telephone

025-52791167,52791168

13390905858

13390905858

Detailed explanation of personalized setting techniques for temperature controllers

Temperature controllers have a wide range of applications in various fields, from creating comfortable environments in homes to precision production in industry. Accurately setting temperature controllers plays a key role in achieving ideal temperature control effects. Next, we will delve into the personalized setting techniques of temperature controllers to help everyone better utilize this device.

1、 Set according to different application scenarios

home environment

Bedroom: The main purpose of using a temperature controller in the bedroom is to create a comfortable sleeping environment. Generally speaking, during summer cooling, the temperature can be set between 26 ℃ -28 ℃. This temperature range can not only make people feel cool, but also avoid catching a cold or increasing excessive electricity bills due to low temperatures. When heating in winter, setting it at 18 ℃ -22 ℃ is more suitable, which is in line with the comfortable feeling of human sleep and also more energy-efficient. Moreover, many bedroom temperature controllers can be equipped with timed functions, such as automatically turning off cooling or heating devices such as air conditioning after several hours before bedtime, which can further save energy while ensuring sleep comfort.

Living room: As the main place for family activities, the living room has relatively frequent personnel flow, and the temperature setting can be relatively flexible. In summer, it can be slightly lowered, around 24 ℃ -26 ℃, to make people feel cooler and more comfortable during leisure and entertainment; In winter, it can be set at 20 ℃ -22 ℃ to maintain a warm and comfortable atmosphere in the entire living room. In addition, for some smart temperature controllers, they can also be linked with smart speakers and other devices at home to adjust the temperature conveniently and quickly through voice commands.

Kitchen: Due to cooking activities, the kitchen generates a lot of heat. The temperature controller should be set lower in cooling mode, such as 22 ℃ -24 ℃ in summer, which can effectively offset the heat generated by cooking and create a relatively comfortable working environment for the cook. However, it should be noted that kitchen fumes may have a certain impact on the temperature controller, and regular cleaning of the equipment is necessary to ensure its normal operation.

industrial production

Food processing workshop: Temperature control is crucial in food processing workshops. For example, in dairy processing, the fermentation process requires strict temperature control within a specific range. For example, yogurt fermentation usually requires a temperature of around 40 ℃ -45 ℃. The temperature controller should be accurately set to this range and have high-precision temperature monitoring and regulation capabilities. Some may also have temperature alarm functions. Once the temperature exceeds the set reasonable range, an alarm will be issued in a timely manner to prevent affecting product quality.

Electronic component production workshop: This type of workshop has strict requirements for temperature and humidity. Generally, the temperature should be controlled between 20 ℃ -25 ℃ and the humidity between 40% -60%. The temperature controller not only needs to accurately set the temperature, but also often needs to be linked with humidity control equipment to ensure that the entire workshop environment meets the precise conditions of electronic component production through an integrated control system, avoiding the performance degradation or even damage of components caused by abnormal temperature and humidity.

2、 Setting and utilizing advanced features

Temperature compensation setting

Some temperature controllers have temperature compensation function, which is very useful in some special environments. For example, in a refrigerator, when the door is frequently opened or there are many high-temperature items placed, the temperature inside the box will fluctuate. By setting temperature compensation, the refrigeration system of the refrigerator can automatically adjust appropriately according to the temperature changes, ensuring that the interior is always maintained at a suitable low temperature and better preserving food. The setting method is usually to find the “temperature compensation” option in the menu, and then select the appropriate compensation value according to the actual usage situation. There are usually several gears to choose from.

Multi stage temperature control settings

In some industrial heat treatment processes or laboratory experiments, different temperatures need to be set according to different stages. For example, in metal heat treatment processes such as quenching and tempering, the quenching stage may require high temperature rapid cooling, while the tempering stage requires relatively low temperature insulation for a longer period of time. The multi-stage temperature control function of the temperature controller can pre-set parameters such as temperature and time for each stage, and then automatically complete the entire temperature control process according to the set program, improving the efficiency and accuracy of production and experimentation.

Remote control and data recording function

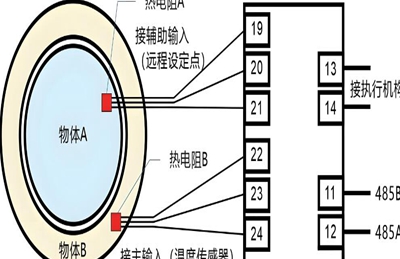

Nowadays, more and more temperature controllers support remote control. By connecting to the network, users can remotely view real-time temperature data on their mobile app or computer and adjust temperature settings. At the same time, it can also record data on temperature changes, which is very helpful for analyzing temperature control effects and tracing production processes. Setting up remote control function generally requires connecting the temperature controller to the corresponding network, registering and configuring the device on the corresponding platform, and completing the binding steps according to the operation prompts.

3、 Daily maintenance and setting adjustment

Regular cleaning and inspection

After long-term use, dust and other debris may accumulate on the surface and inside of the temperature controller, affecting heat dissipation and normal operation. Regularly clean it by wiping the surface with a clean and soft cloth. For areas with heat dissipation holes, gently blow away dust with the cold air setting of a hair dryer. At the same time, check whether the buttons are sensitive, whether the display screen is clear, etc., and promptly deal with any problems found.

Adjust settings based on seasonal and usage changes

The environmental temperature varies in each season, and the usage needs of households and industrial sites also change, so it is necessary to adjust the temperature controller settings in a timely manner. For example, from summer to winter, it is necessary to switch the cooling mode to the heating mode and reset the appropriate target temperature to ensure that it always meets the actual temperature control requirements.

By mastering these personalized setting techniques and performing daily maintenance and adjustment work, we can maximize the efficiency of the temperature controller and provide better temperature control services for life and production.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100