Telephone

025-52791167,52791168

13390905858

13390905858

Installation and Maintenance of Pneumatic Diaphragm Valve: Installation Process and Key Points

1、 Installation process and key points

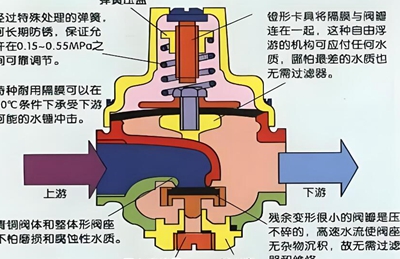

Pneumatic diaphragm valves play a key role in fluid control in many industrial fields due to their unique structure and performance advantages. Correct installation is the primary condition for ensuring efficient operation and extending the service life of valves. This article will elaborate on the installation points of pneumatic diaphragm valves from the perspective of installation technology.

2、 Careful preparation before installation

Valve body inspection

After receiving the pneumatic diaphragm valve, the first step is to thoroughly inspect the valve body. It is crucial to verify whether the model, specifications, and design requirements of the valve are consistent, as incorrect models or specifications may result in inability to meet actual operating requirements. Carefully inspect the appearance of the valve, check for any casting defects, bumps, or scratches on the valve body, and pay special attention to any signs of damage or aging on the diaphragm. Once the diaphragm is damaged, it will directly damage the sealing performance of the valve, leading to serious problems such as leakage. The integrity of the diaphragm can be observed from all angles through strong light irradiation.

Pipeline pretreatment

The pipeline connected to the valve needs to undergo strict pre-treatment. Impurities such as welding slag, rust, and debris inside the pipeline can enter the valve when it is opened or closed, causing wear on the diaphragm and other components. A combination of mechanical cleaning (such as wire brushes, pipe cleaners) and chemical cleaning (such as acid washing, alkali washing) is used to thoroughly remove impurities from the pipeline. At the same time, measure the size parameters such as inner diameter, outer diameter, and ellipticity of the pipeline to ensure a good match between the pipeline and the valve connection, and avoid excessive installation stress caused by size deviation.

3、 Accurate installation process

Determine the optimal installation location

The selection of installation location has a significant impact on the performance of pneumatic diaphragm valves. Priority should be given to selecting a location that is easy to operate and maintain, for example, at least 500mm of space should be reserved around the handwheel for operators to manually open and close the valve. Avoid installing valves in low-lying areas of pipelines to prevent the accumulation of impurities in the medium from affecting the normal operation of valves. If installed outdoors, consideration should be given to setting up a protective shed to prevent damage to the valve from rainwater and direct sunlight.

Correct implementation of connection methods

Flange connection: This is the most common connection method. Align the valve with the flange of the pipeline, ensuring that the bolt holes are completely aligned. Place suitable sealing gaskets between the flange sealing surfaces, and the gasket material should be selected according to the characteristics of the medium and the working temperature. Symmetrically tighten the bolts, gradually tightening them in diagonal order, with an even degree of tightening each time, to balance the force on the flange sealing surface and prevent leakage.

Threaded connection: For small-diameter valves, threaded connections are more commonly used. Apply an appropriate amount of sealant on the threads to enhance the sealing effect. When screwing the valve into the pipeline, pay attention to the direction and force of rotation to avoid thread damage. Use a torque wrench to tighten according to the specified torque, ensuring a secure connection.

Installation and commissioning of pneumatic actuators

Accurately connect the pneumatic actuator to the valve body and secure it using specialized connectors. During the connection process, ensure that the action axis of the actuator is concentric with the drive axis of the valve, otherwise it may cause the actuator to malfunction or the valve to fail to open and close normally. After connecting the pneumatic pipeline, introduce compressed air for debugging. Adjust the air pressure, observe the speed and stroke of the actuator, and ensure that the valve can be quickly and accurately opened and closed.

4、 Strict inspection after installation

Sealing inspection

Use airtight test or hydrostatic test to inspect the sealing of the valve. During the airtightness test, compressed air is filled into the valve chamber, and after the pressure reaches the specified value, soapy water is applied to the sealing part of the valve to observe whether bubbles are generated. The hydrostatic test requires injecting water into the valve, slowly increasing the pressure to the specified level, holding it for a certain period of time, and checking for any leaks in various parts of the valve.

Reliability testing of actions

Manually operate the valve and check whether the handwheel rotates flexibly and whether the valve opening and closing positions are accurate. Then, through the pneumatic control system, the valve performs multiple opening and closing actions, recording the time, stroke, and response of each action. If any abnormal actions are found, such as lagging or delay, promptly investigate the cause of the malfunction, such as actuator failure, air path blockage, etc.

The correct installation process is the foundation for the stable operation of pneumatic diaphragm valves. Only by strictly following the installation points can the performance of the valve be fully utilized, ensuring the smooth progress of industrial production.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100