Telephone

025-52791167,52791168

13390905858

13390905858

Solution for poor buffering effect of cylinder.

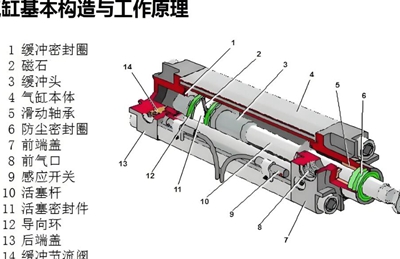

As an essential component in the field of industrial automation, the stability of cylinder performance directly affects the operational efficiency and reliability of the entire equipment. In practical use, cylinders may experience various malfunctions. Below, we will provide a detailed introduction to some common faults and corresponding solutions.

1、 Poor buffering effect of cylinder

During the operation of the cylinder, there may be situations where the buffering effect is not ideal, resulting in a significant impact force at the end of the stroke. This not only affects the stability of the equipment, but may also shorten the service life of the cylinder and related components.

Buffer control valve malfunction: The buffer control valve is a key component that controls the buffering effect of the cylinder. If the adjustment of the control valve is improper or malfunctions, such as the valve core getting stuck or the adjusting nut becoming loose, it can lead to poor buffering effect. The solution is to check the adjustment of the buffer regulating valve and make adjustments according to actual needs. If the regulating valve malfunctions, it should be repaired or replaced in a timely manner. When adjusting the buffer regulating valve, pay attention to gradually adjusting it to avoid adjusting it too much at once, which may result in a strong or weak buffering effect.

Damaged buffer seal ring: The function of the buffer seal ring is to seal the buffer chamber when the cylinder approaches the end of its stroke, compressing the gas inside the chamber and producing a buffering effect. If the buffer sealing ring is damaged, it will cause gas leakage in the buffer chamber and reduce the buffering effect. The solution is to check the condition of the buffer seal ring and replace it promptly if any damage is found. Choose high-quality and strong sealing gaskets to ensure the buffering effect.

Unreasonable buffer chamber design: In some cases, there may be unreasonable aspects in the buffer chamber design of the cylinder, resulting in unsatisfactory buffering effect. For this situation, it may be necessary to modify or replace the cylinder with a suitable one. You can communicate with the cylinder manufacturer or professional technicians to optimize the design of the buffer chamber of the cylinder according to actual work requirements.

2、 Unstable cylinder speed

The unstable operating speed of the cylinder can affect the working accuracy and production efficiency of the equipment. The main reasons for unstable cylinder speed are as follows:

Flow control valve malfunction: The flow control valve is used to control the gas flow entering the cylinder, thereby regulating the operating speed of the cylinder. If the flow control valve malfunctions, such as valve core wear or inaccurate adjustment, it can cause unstable gas flow into the cylinder, resulting in unstable cylinder speed. The solution is to check the working status of the flow control valve and repair or replace the valve core. According to the working requirements of the cylinder, accurately adjust the flow control valve to ensure stable gas flow.

Changes in pipeline resistance: If the pipeline connecting the cylinder is bent or blocked, it will cause changes in pipeline resistance, thereby affecting the intake volume and speed of the cylinder. The solution is to check the connection of the pipeline, ensure that it is unobstructed, and avoid excessive bending or blockage. For longer pipelines, the diameter of the pipeline can be appropriately increased to reduce pipeline resistance.

Load variation: If the load driven by the cylinder changes during operation, such as the weight and friction of the load, it can also cause unstable cylinder speed. The solution is to adjust the operating parameters of the cylinder according to the changes in load. Proportional valves and other control components can be used to adjust the intake and output force of the cylinder in real time according to changes in load, in order to ensure stable cylinder speed.

3、 Cylinder piston rod fracture

The fracture of cylinder piston rod is a serious fault that can cause equipment shutdown and affect production progress. The main reasons for piston rod fracture are as follows:

Overload operation: If the cylinder is subjected to a load exceeding its rated load during operation, it may cause excessive stress on the piston rod, which may lead to fracture. The solution is to strictly follow the rated load of the cylinder and avoid overloading operation. When selecting a cylinder, it is necessary to choose the model and specifications of the cylinder reasonably according to the actual working requirements, to ensure that it can withstand the required load.

Material issue of piston rod: If the material of the piston rod does not meet the requirements, such as insufficient strength and toughness, it will also increase the risk of piston rod fracture. The solution is to choose a piston rod with reliable quality and ensure that its material meets relevant standards and requirements. When purchasing piston rods, it is necessary to check the quality certification documents of the product and inspect the material.

Improper installation: Incorrect installation of the piston rod, such as deviation or distortion during installation, can cause additional stress on the piston rod during operation, leading to fracture. The solution is to recheck the installation of the piston rod to ensure that it is installed correctly and securely. During the installation process, appropriate tools and methods should be used to avoid damage to the piston rod.

By analyzing the common faults of the above cylinders and introducing solutions, we hope to help everyone better maintain and manage the cylinders, and improve the reliability and stability of equipment operation. In practical work, it is necessary to strengthen the daily maintenance and inspection of cylinders, timely discover and solve problems, and ensure the normal operation of equipment.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100