Telephone

025-52791167,52791168

13390905858

13390905858

The daily maintenance method of solenoid valve coil

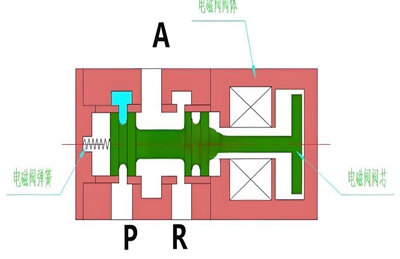

As an indispensable component in automation control systems, the normal operation of solenoid valves’ coils directly affects the stability and reliability of the entire system. Therefore, scientific and effective daily maintenance of solenoid valve coils is crucial.

When the solenoid valve coil is working, it generates a magnetic field through current, which drives the valve core to move. During long-term operation, it is inevitable to be affected by various factors, leading to a decrease in performance or even malfunctions. In daily maintenance, the appearance of the solenoid valve coil should be carefully inspected first. Check the surface of the coil for any damage, cracks, or burnt marks, which may indicate that the coil has been severely damaged and needs to be replaced in a timely manner. At the same time, check whether the leads of the coil are firmly connected, whether they are loose, detached, or oxidized. Poor connection of the leads can lead to poor current transmission, affecting the normal operation of the solenoid valve.

Temperature is also one of the important factors affecting the performance of solenoid valve coils. Excessive temperature can cause a decrease in the insulation performance of the coil, accelerating its aging and damage. Therefore, in daily maintenance, attention should be paid to monitoring the working temperature of the solenoid valve coil. A thermometer or infrared thermometer can be used to measure the temperature of the coil surface, ensuring that its operating temperature is within the specified range. If the temperature is found to be too high, it is necessary to promptly investigate the cause, which may be due to poor heat dissipation, excessive load, or abnormal power supply voltage. For poor heat dissipation, it is possible to check whether there are obstacles around the coil that block heat dissipation, or to add heat dissipation devices to improve the heat dissipation conditions.

In addition to temperature, humidity is also an aspect that needs attention. A humid environment can reduce the insulation performance of the coil and increase the risk of short circuits. When using solenoid valves in environments with high humidity, corresponding moisture-proof measures should be taken. For example, a protective cover can be installed for the solenoid valve to prevent moisture from directly contacting the coil; Alternatively, insulation materials with moisture-proof properties can be used to protect the coil. At the same time, regularly conduct insulation resistance tests on the coils to ensure that their insulation performance meets the requirements.

The working power supply of the solenoid valve coil also needs to be strictly monitored. Excessive or unstable fluctuations in power supply voltage can have adverse effects on the lifespan of the coil. Use a stable power supply and equip it with overvoltage and undervoltage protection devices. In daily maintenance, it is necessary to regularly check whether the power supply voltage is within the specified range. If there are any abnormalities, they should be adjusted or repaired in a timely manner. In addition, it is important to pay attention to whether the frequency of the power supply matches the rated frequency of the solenoid valve coil, otherwise it will also affect the normal operation of the solenoid valve.

Regular cleaning of solenoid valve coils is also an important part of daily maintenance. Impurities such as dust and oil on the surface of the coil can affect its heat dissipation performance and may also lead to a decrease in insulation performance. You can use a clean cloth or brush to clean the surface of the coil, and for stubborn stains, a specialized cleaning agent can be used for cleaning. During the cleaning process, be careful not to damage the insulation layer of the coil.

In short, the daily maintenance of solenoid valve coils is a meticulous and important task. Through comprehensive inspection and maintenance of appearance, temperature, humidity, power supply, and other aspects, potential problems can be identified and resolved in a timely manner, extending the service life of solenoid valve coils, ensuring the normal operation of solenoid valves, and thus improving the reliability and stability of the entire automation control system.

telephone:025-52791167,52791168

Fax:025-52791169

Phone :13390905858

mailbox:njxj888@163.com skype:yluedq

Address:Jiangning Shuanglong Avenue No.1222 Nanjing, Jiangsu. China P.O. 211100