The principle and application of normally open and normally closed

differential pressure switches

Differential pressure switch is a special control switch that relies on electrical signal transmission to control the closure or opening of the switch. Its normally open or normally closed state depends on the actual application scenario and requirements.

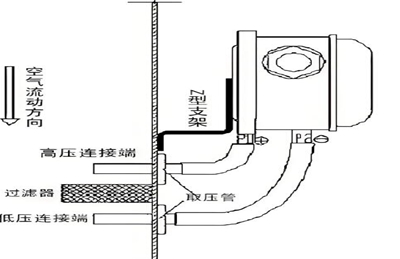

In principle, a differential pressure switch typically consists of two bellows chambers, namely a high pressure chamber and a low pressure chamber. When the pressure difference between the high-pressure chamber and the low-pressure chamber reaches the set value, the pressure sensing film will deform, and the micro switch will be pushed by the internal mechanical structure to emit an electrical signal, causing the switch to close or open.

When the normally open differential pressure switch is not subjected to pressure, the contacts are in a disconnected state; When the pressure difference reaches the set value, the contacts will close, thereby conducting the circuit and emitting a signal. For example, in some air conditioning systems, it is used to monitor the pressure difference between the two ends of the air filter. When the filter gradually becomes clogged and the pressure difference between the two ends increases to the set value, the normally open pressure difference switch closes, sending a signal to notify maintenance personnel that the filter needs to be replaced. This design ensures that the circuit is in a disconnected state when the filter is working properly, reducing unnecessary energy consumption and false alarms.

A normally closed differential pressure switch has its contacts in a closed state when not subjected to pressure; When the pressure difference reaches the set value, the contact opens. For example, in some applications of fire protection systems, normally closed differential pressure switches can be installed in ventilation ducts on both sides of fire doors. Under normal circumstances, the contacts are closed and the system is in a monitoring state. Once a fire occurs, the pressure difference on both sides of the fire door changes. When the pressure difference exceeds the set value, the contact of the normally closed pressure difference switch opens, triggering the action of related equipment, such as starting the positive pressure blower, to ensure that the pressure difference on both sides of the fire door remains within a safe range and prevent smoke from entering the fire zone.

When choosing the normally open or normally closed state of a differential pressure switch, multiple factors need to be considered comprehensively. Firstly, there is a safety factor. For situations that require high safety standards, such as those involving gas or liquid leak detection, normally closed differential pressure switches are more suitable. Because under normal circumstances, the contacts are closed. Once an abnormal situation occurs that causes a change in pressure, the contacts immediately disconnect, which can trigger an alarm or take safety measures in a timely manner. For some systems that require specific pressure differential conditions to start the relevant equipment, normally open pressure differential switches are more commonly used to avoid equipment misoperation caused by small pressure fluctuations during normal system operation.