Reason analysis and treatment methods for

pressure switch not jumping

As an important pressure control component in industrial control systems, pressure switches play a crucial role in maintaining normal system operation and ensuring safety. However, in actual use, there may be situations where the pressure switch does not trip, which not only affects the normal operation of the equipment but may also pose safety hazards. This article will conduct a thorough analysis of the reasons why the pressure switch does not trip and explore corresponding solutions.

A common reason for

pressure switches not to trip is inaccurate setting values. If the set value of the pressure switch is too high, the pressure switch will still not operate when the system pressure reaches the upper limit of the normal working range. On the contrary, if the set value is too low, it may cause frequent misoperation of the pressure switch. Therefore, before installing and using the pressure switch, it is necessary to accurately set the action value and reset value of the pressure switch. Professional pressure calibration equipment can be used to calibrate the pressure switch, ensuring that its set value meets the actual needs of the system.

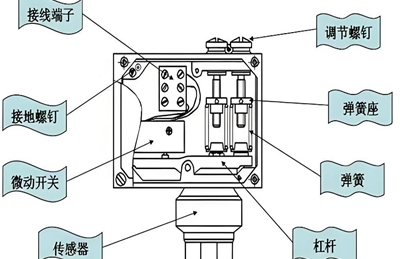

In addition, mechanical failure of the pressure switch may also cause it to not trip. For example, problems such as micro switch damage, spring fatigue or jamming, and membrane rupture may affect the normal operation of pressure switches. In case of damage to the micro switch, it is necessary to replace it with a new one in a timely manner; When the spring is fatigued or stuck, the elasticity and flexibility of the spring should be checked, and the spring should be replaced if necessary; If the membrane ruptures, it needs to be replaced. When repairing and replacing components, it is important to choose the appropriate model and specifications to ensure compatibility with the pressure switch.

The connection issue of the pressure switch is also a factor that cannot be ignored. If the signal wire connection of the pressure switch is loose, short circuited, or disconnected, it will cause the pressure switch to malfunction. Therefore, when installing and using pressure switches, it is important to ensure that the signal lines are securely connected and not damaged. At the same time, it is necessary to regularly check the connection status of signal lines, promptly detect and handle connection problems. In addition, blockage or leakage of the pressure switch’s pressure pipe can also affect its normal operation. Blockage of the pressure pipe can result in inaccurate transmission of pressure to the pressure switch, while leakage of the pressure pipe can lead to inaccurate pressure measurement. For situations where the pressure pipe is blocked, compressed air or cleaning solution can be used for cleaning; If the pressure pipe leaks, it needs to be repaired or replaced in a timely manner.

Environmental factors may also have an impact on the operation of pressure switches. For example, environmental conditions such as high temperature, humidity, and corrosion may cause damage or performance degradation of pressure switch components. In this case, corresponding protective measures need to be taken, such as installing protective covers and using components made of corrosion-resistant materials. At the same time, regular maintenance and upkeep of pressure switches should be carried out, dust and dirt should be cleaned in a timely manner, and the working condition of components should be checked to ensure that they can still function normally in harsh environments.

When encountering situations where the pressure switch does not trip, we need to analyze and troubleshoot from multiple aspects such as set values, mechanical faults, connection issues, and environmental factors to identify the root cause of the problem and take corresponding measures. Only in this way can we ensure the normal operation of the pressure switch and guarantee the safe and stable operation of the industrial control system.

#Keywords:

pressure switch; Not jumping; Set value; Mechanical failure; Connection issues; environmental factor