The difference between

pressure switch and pressure transmitter

In the field of industrial automation control and various systems involving pressure monitoring, pressure switches and pressure transmitters are two common pressure measurement and control devices. Although they are all related to stress, there are significant differences in their functions, principles, and application scenarios.

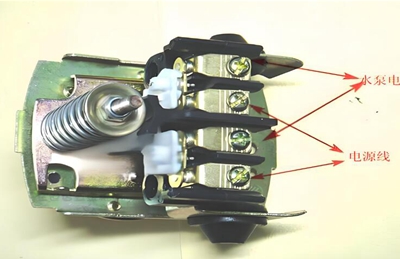

From a functional perspective, pressure switches are mainly used to achieve pressure control and alarm functions. It is set with one or more pressure action points, and when the measured pressure reaches these set values, the contacts of the pressure switch will act, thereby connecting or disconnecting the circuit. For example, in the water pump control system, when the water pressure is lower than the set value, the pressure switch will activate and start the water pump to replenish water; When the water pressure reaches the upper limit set value, the pressure switch will operate again to stop the water pump from working. It serves as an output switch to control the start stop or trigger alarm devices of the equipment.

The main function of a pressure transmitter is to accurately convert pressure signals into standard electrical signal outputs, such as 4-20mA, 0-10V, etc. It can continuously measure the magnitude of pressure and convert it into corresponding electrical signals, which are transmitted to the control system or display instrument, so that operators can understand the specific value of pressure in real time.

Pressure transmitters focus on precise measurement of pressure and remote transmission of signals, providing analog pressure data for analysis, control, and monitoring of the system.

In terms of principle, the working principle of pressure switches is relatively simple. Common types include mechanical diaphragm type, corrugated tube type, etc. Taking the mechanical diaphragm type as an example, when pressure is applied to the diaphragm, it will deform. When the deformation reaches a certain degree, it will push the internal mechanical structure, causing the contacts to close or open. This structure is simple and reliable, but the accuracy is relatively low.

The principle of pressure transmitters is more complex and diverse. Capacitive pressure transmitters use changes in capacitance to measure pressure. When the pressure changes, the distance or area between the plates of the capacitor will change, resulting in a change in the capacitance value. The change in capacitance value is converted into an electrical signal output through a circuit. The diffusion silicon pressure transmitter utilizes the piezoresistive effect of silicon. When pressure is applied to the diffusion silicon chip, the resistance value of the chip will change. The resistance change is converted into a voltage signal through circuits such as Wheatstone bridge, and then amplified to obtain a standard output signal.

From the perspective of application scenarios, pressure switches are commonly used in situations where pressure control accuracy is not particularly high and only simple pressure upper and lower limit control and alarm are required. Such as water level control in the water tank, start stop control of the air compressor, etc.

Pressure transmitters are widely used in situations where precise pressure measurement, data processing, and control are required. In the petrochemical industry, it is used to measure the pressure inside pipelines and provide accurate pressure data for the control of production processes; In the power industry, it is used to measure the steam pressure inside boilers to ensure their safe operation.

In summary, although both pressure switches and pressure transmitters are related to pressure measurement, they have significant differences in functionality, principles, and application scenarios. In practical applications, it is necessary to select appropriate equipment based on specific needs and operating conditions to ensure the stable operation and effective control of the system.

#Keywords: pressure switch; Pressure transmitter; Functional differences; Principle differences; Application scenarios